The Compounding Bubble Film Making Machine is outfitted with seven precision-engineered units, including the Extruder, Vacuum Forming Bubble Roller, Trimming, Wastage Collection, Balancing, Winder, and Electrical System. This advanced machinery is primarily designed for the production of high-quality 3-5 layer bubble film, with customization options to produce a maximum of 7 layers. With its broad range of potential applications, this state-of-the-art machine is an excellent investment for businesses seeking to expand their product offerings and meet the demands of diverse markets.

Product description

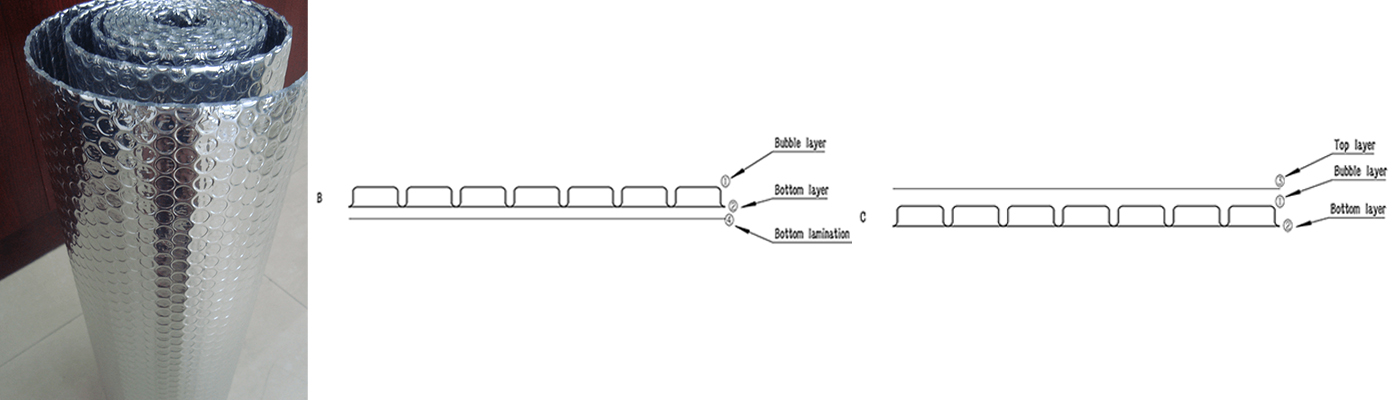

3-layer bubble film is a protective packaging material consisting of three layers of polyethylene film with air-filled bubbles in between. It provides excellent cushioning and shock absorption, is lightweight and flexible, and has insulating properties. It's widely used in various industries, including e-commerce and manufacturing, for packaging fragile items during shipping and handling.

5layer Bubble Film

Comparing with traditional models,this model add one extruder, one compounding unit and two material shaft. Entire machine use PLC touch screen automatic control to make different kind of compounding products.

In real manufacturing, this machine can achieve full automatic function from material feeding to end product winding and changing. Easy Operation, stable working, low invest and high output.

Usable Material

Bubble Film machine use material LDPE MFI=2~7 as main material,can mix with LLDPE MFI=1.0~1.5 as support material, or use recycle LDPE MFI=2~4 as base material, to make bubble film products.

Main Technical Parameters

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-3000 |

|

Main Screw Dia |

90 |

90 |

100 |

|

Minor Screw Dia |

70 |

70 |

80 |

|

Finished Film Width |

1600 |

2000 |

3000 |

|

Output |

180kg |

230kg |

280kg |

|

Main Extruder Motor |

45kw |

45kw |

55kw |

|

Sub-Extruder Motor |

22kw |

22kw |

37kw |

|

Total Power |

156kw 加热95kw |

210kw 加热125kw |

300kw加热178kw |

|

L/D |

34:1 |

34:1 |

34:1 |

|

Power Supply |

380/3/4/50(Volt/Ph/Line/Hz) |

380/3/4/50(Volt/Ph/Line/Hz) |

380/3/4/50(Volt/Ph/Line/Hz) |

|

Weight |

12000*4800*3200mm |

12000*5100*3200mm |

12000*5500*3200mm |

|

Overall Dimension(LxWxH)mm |

11ton |

13ton |

15ton |

Optional Parts

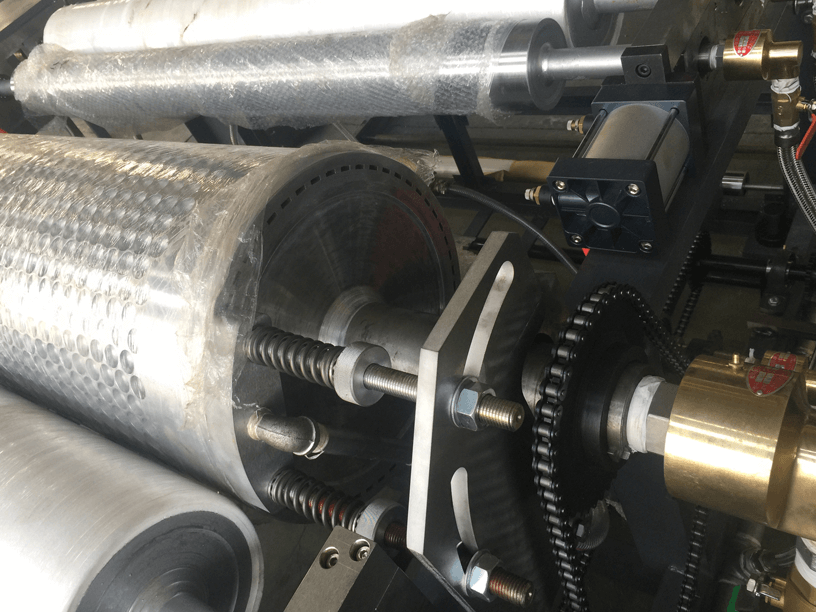

1.Side Sucking Forming Roller, Less Sucking Variation and Better Chilling Ability.

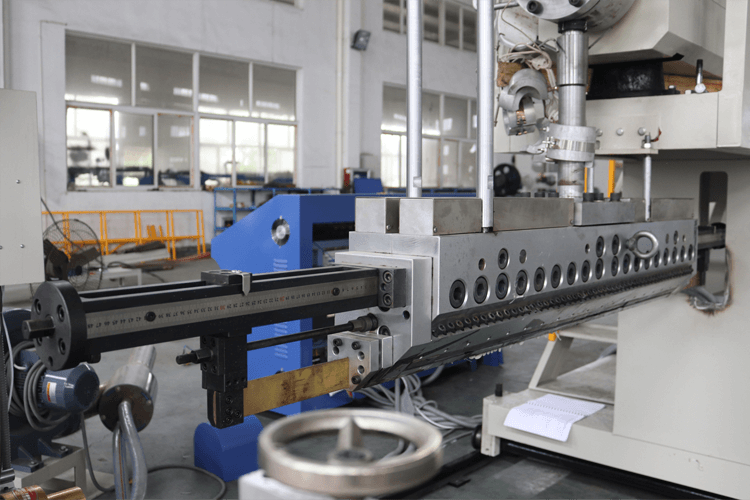

2.Lamination Grade T-Die, to improve product quality, make sure T-Die Blocking without changing of T-Die Pressure, no matter how much you block, material coming out always in even form.

3.Unwinder with Automatic Tension and EPC

4.New Design of Winder which allows you to wind Big Jumbo Rolls max to 1500mm without making winder size too high. Save wastage and reduce labor work.

New Design Winder with Meg Tension Control and Converter Speed Control. Making Sure winding roll quality.

If you have any enquiry about quotation or cooperation,please feel free to email us atadmin@hlgplastic.comor use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.