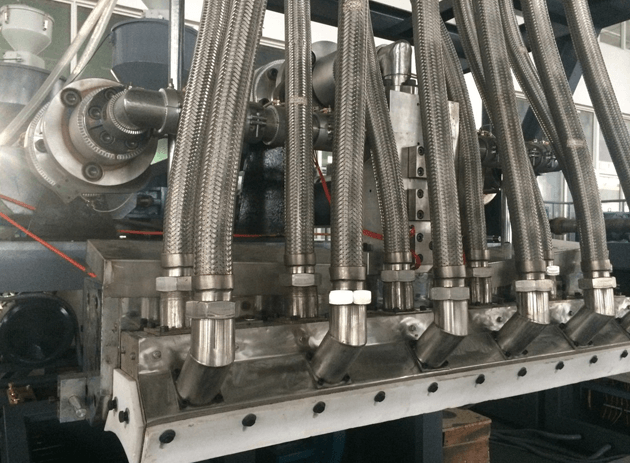

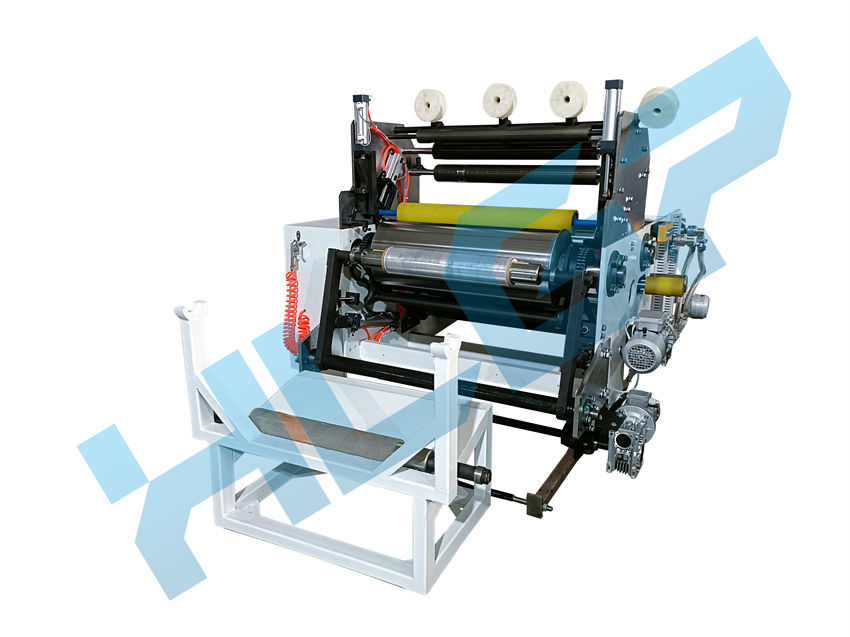

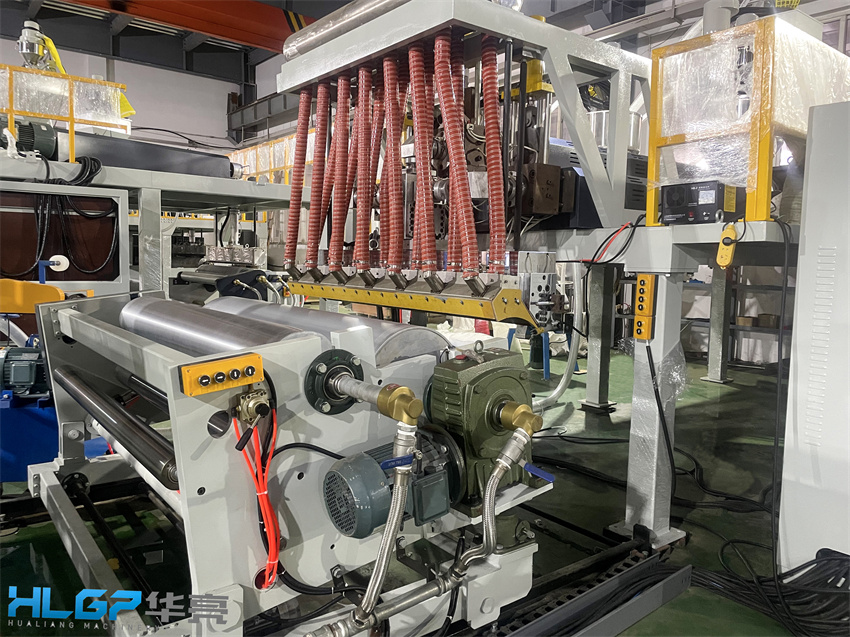

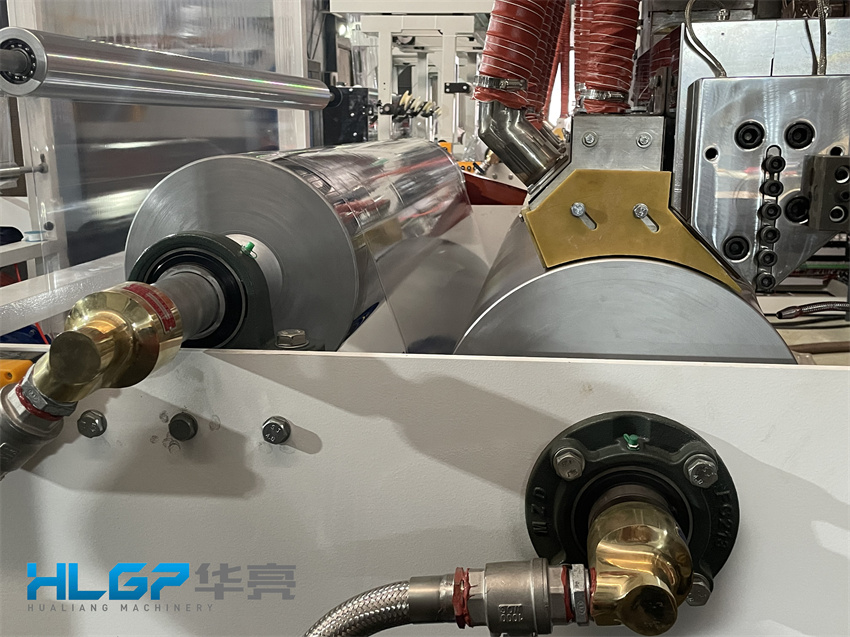

This machine uses LDPE or LLDPE as material to produce casting stretch film. Three Screw Co-Extrusion, each screw allow different formulas to produce single side sticky stretch film, Mainly used for machine wrap type stretch film making. Screw and Barrel use 38CrMoAIA Alloy steel, after nitriding and special treatments. Machine cooling with water circulation, best cooling effect and best transparency of stretch film.

Product description:

Highlight

This machine uses LDPE or LLDPE as material to produce casting stretch film. Three Screw Co-Extrusion, each screw allow different formulas to produce single side sticky stretch film, Mainly used for machine wrap type stretch film making. Screw and Barrel use 38CrMoAIA Alloy steel, after nitriding and special treatments. Machine cooling with water circulation, best cooling effect and best transparency of stretch film.

Cutter Blade Winder

Vacuum System

Online Recycle (Optional)

Parameters Table:

|

Model |

JDCPE80/60/60A-1500 |

|

Screw Dia |

Φ80mmΦ60mmΦ60mm |

|

L/D |

30:1 |

|

Product Width |

500-1500mm |

|

Film Thickness |

0.01-0.03mm |

|

Design Line Speed |

80m/min |

|

Production Capacity |

120kg/h |

|

Main Motor |

30kw/18.5kw/18.5kw |

|

Heating Power |

86kw |

|

Total Power |

164kw |

|

Weight |

9000kg |

|

OveralDemension |

8000mm×4500mm×1900mm |

|

Power Supply |

380/3/4/50(Volt/Ph/Line/Hz) |

Note:

Our machines can be custermized according to different requests,such as: Width 1-2meter, layer 2-7 layers, so clients can always match their market request.

Due to the continuous improvement of the products, the appearance and technical parameter subject to change without notice.

Equipment photo:

If you have any enquiry about quotation or cooperation,please feel free to email us atadmin@hlgplastic.comor use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.