1.Speed design: up to 150 M/min.

2. Working speed: 80~120 M/min.

3. Production capacity: 80~20 KGS/H (depends on the film thickness and line speeds).

4. Quality stretch film which can compare with the film produced by European machines.

|

No. |

Item |

Specs |

|

1. |

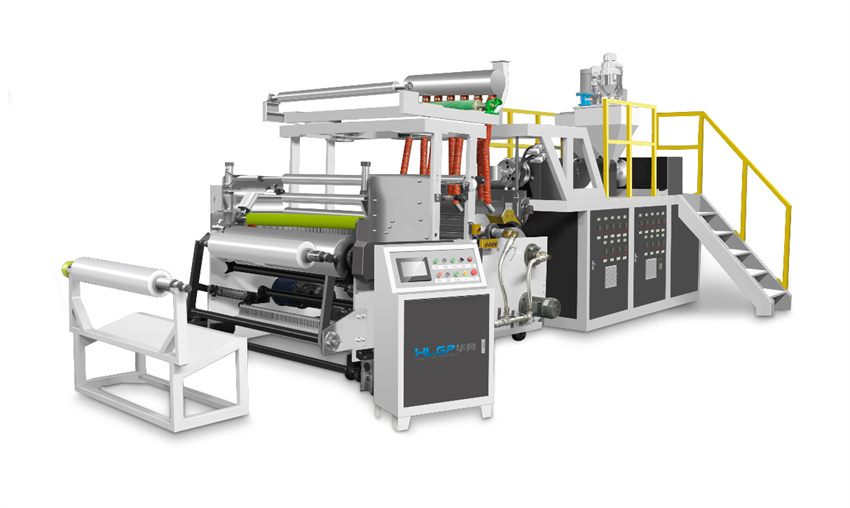

Model: |

HLCPE-1000-80/60 |

|

2. |

Industrial Power Supply: |

3 phases industrial power supply |

|

3. |

Total Power: |

100 KW |

|

4. |

Main Raw Material: |

LLDPE, LDPE (few) & MLLDPE |

|

5. |

Thickness of Film: |

12~50 microns (minimum thickness can be 8 microns) |

|

6. |

Width of the Useful Film: |

Maximum width: 1000 mm |

|

7. |

Film Layer Structure: |

AB two layers or ABA three layers |

|

8. |

Designed Linear Speed: |

150 M/Min |

|

9. |

Extrusion Output: |

80~150 kgs/h |

|

10. |

Dimensions (L×W×H): |

7*3*2 M (for reference only) |

|

11. |

Gross Weight: |

5500 (for reference only) |

Highlights on machine performances:

1.Speed design: up to 150 M/min.

2. Working speed: 80~120 M/min.

3. Production capacity: 80~20 KGS/H (depends on the film thickness and line speeds).

4. Quality stretch film which can compare with the film produced by European machines.

5. Excellent production capacity and power consumption ratio: around 0.38 KWH/KG.

6. One worker can operate 1-3 machines

Highlights on machine configuration:

1.L/D ratio:34:1,It improves the plasticization of the plastic material.

2. Nitriding treatment makes screws more stable and durable.

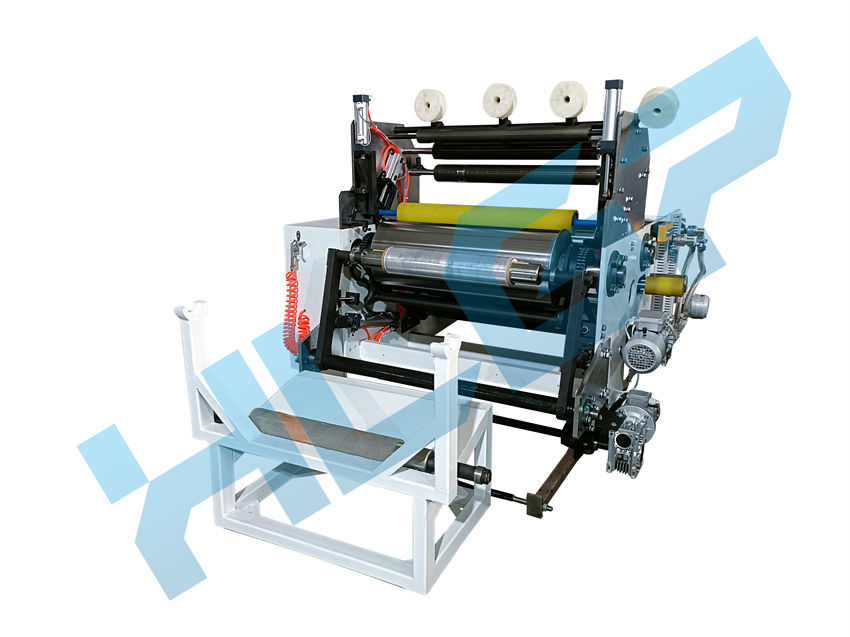

3.Fully automatic metering, automatic rewinding, automatic roll changing.

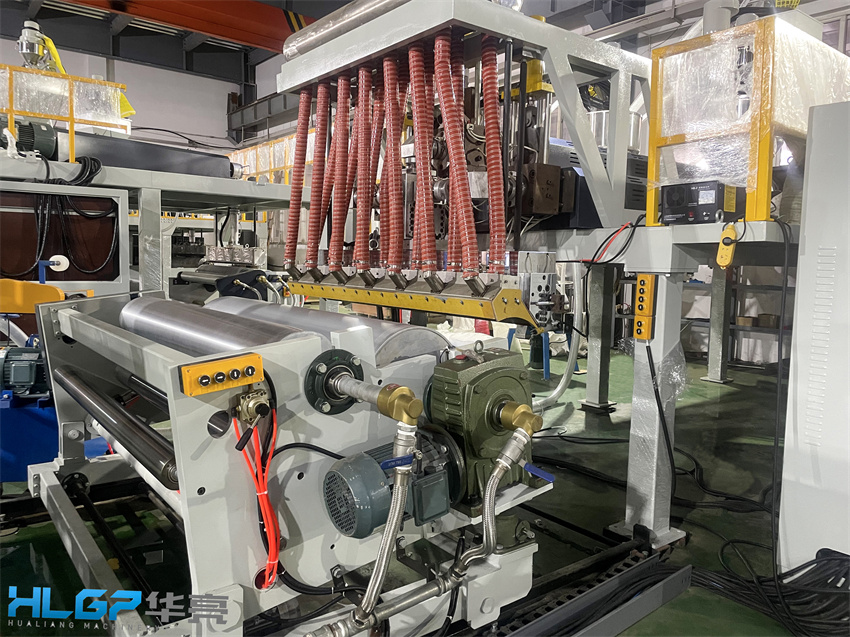

4.The T-die material is 2311 mold steel that ensures a more uniform film and longer lifespan.

5. Metal hoses are used to connect water fittings and provide better cooling.

If you have any enquiry about quotation or cooperation,please feel free to email us atadmin@hlgplastic.comor use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.