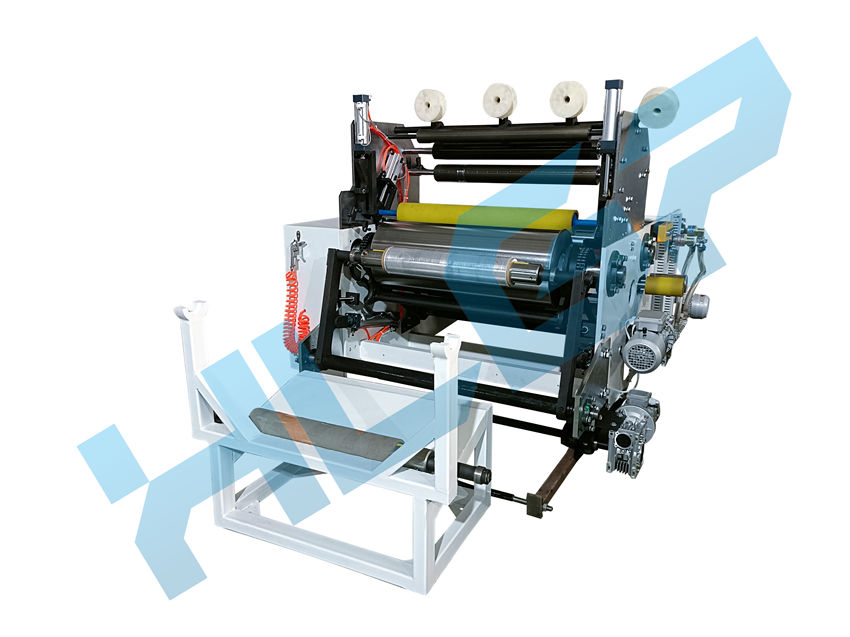

Cast Stretch Film Line complete set hardware parts build with high quality material, which makes the whole machine into a strong/stable running condition

1. The ouput is 250m/min & 350-400kg/hr

2. Layer structure : A/B/C/A/B

Cast Stretch Film Line

Hightlight:

1) Machine complete set hardware parts build with high quality material, which makes the whole machine into a strong/stable running condition;

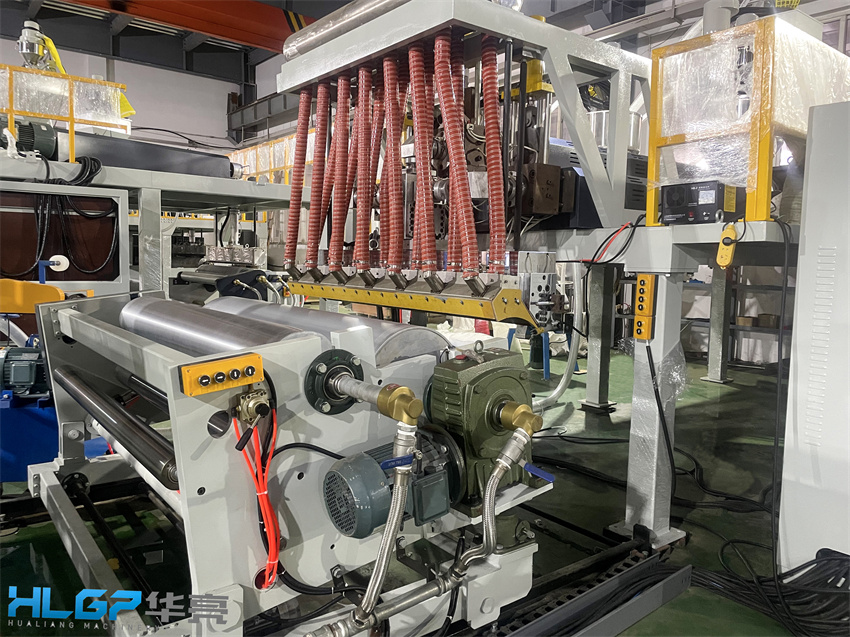

2) Machine software part is with PLC control system, performed with touch screen, which is easy operation ;

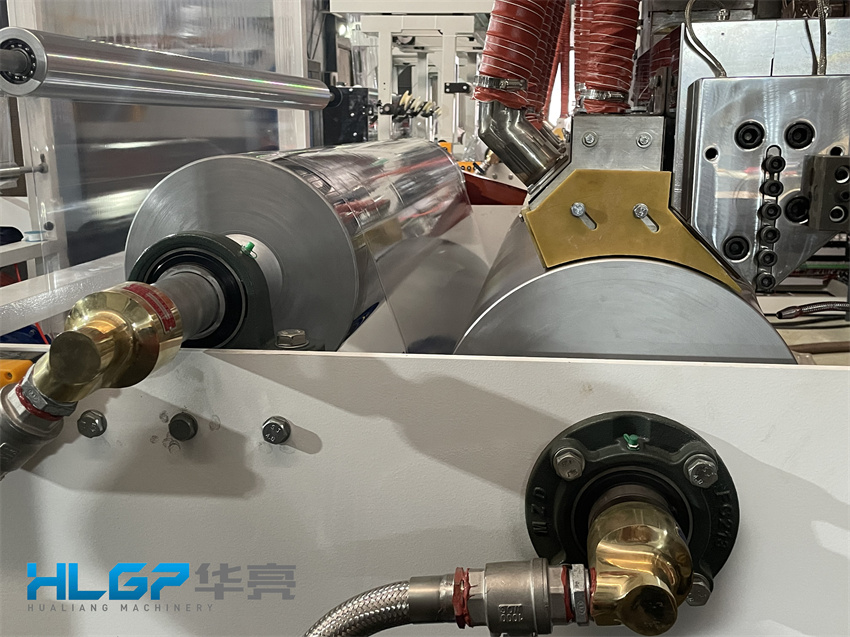

3) Screw length and diameter ratio: 33:1, for perfect Plasticizing advantage;

4) Ceramic heater in screw performs good heating impression and long life;

5) Liquid glue injection device to convenient glue feeding;

6 ) JC TIMES T-DIE, makes the film thickness even;

7) dehumidify system for T-die part, makes the film with super transparency;

8) Edge trim recycling & feeding back system, makes the edge trimmed film directly re-use online, saves the waste;

9) automatic cutting & winding system, with servo control for accurate cutting;

10) Equipped with thickness gauge system for easier adjustment for film thickness;

11) turnkey project for buyer with engineer’s visit to Buyer’s factory for installation and technical guide, support & training

If you have any enquiry about quotation or cooperation,please feel free to email us atadmin@hlgplastic.comor use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.